When we first started our plumbing business, we did what most folks in the industry did: we used flat-rate pricing. It was simple, straightforward, and what everyone else seemed to be doing.

But as time went on, we noticed that our profits were all over the place. Some jobs were gold mines, while others barely covered costs. We realized that flat-rate pricing wasn’t accounting for the nuances of each job, and that was affecting our bottom line.

That’s when we began exploring cost-plus pricing, breaking down costs into specific categories and applying different markups to each. This approach not only stabilized our profits but also gave us a competitive edge. And let us tell you about the time our trusty water jetter taught us a valuable lesson about equipment margins and market pricing.

Breaking Down the Water Jetter Myth

For those not in the plumbing game, a water jetter is a high-pressure machine used to clear out stubborn sewer clogs. It’s an expensive piece of equipment, and traditionally, we charged a hefty fee when we used it—just like everyone else.

One day, while reviewing our costs using our new cost-plus pricing model, we decided to take a closer look at the water jetter. We broke down its costs into several categories:

- Equipment Cost: Purchase price, expected lifespan, maintenance, and repair costs.

- Usage Frequency: How often we actually used the jetter on jobs.

- Storage and Transportation: Costs associated with keeping and moving the equipment.

After crunching the numbers, I was shocked. The actual hourly cost of operating the water jetter was much lower than we had assumed. Meanwhile, the market was charging customers about 500% more than this cost!

This was a lightbulb moment. We realized we could significantly lower our price for jetter services, still maintain a hefty margin, and attract more customers by undercutting the competition.

Breaking Down Costs by Categories

Our revelation with the water jetter led us to dive deeper into how we priced our services. We started breaking down every job into six cost categories:

- Labor

- Materials

- Vehicle

- Subcontractor

- Equipment

- Other

Why these categories? Because each one commands different margins, and understanding this is key to effective pricing.

1. Labor

- Low Markup Margin: Customers are often sensitive about labor costs because they’re familiar with industry rates. If you mark up labor too much, they might balk or shop around.

- Price Elasticity: Labor rates are somewhat inflexible due to market standards. We had to stay competitive here.

2. Materials

- Standard Markup Margin: Typically marked up around 35%, but here’s the kicker—we often received discounts from our suppliers. So, we’d mark up from the regular retail rate, not our discounted rate, leading to an overall margin of 50% or more!

- Customer Perception: Customers expect materials to be marked up but may check prices. Being transparent by listing materials can build trust.

3. Equipment

- High Markup Margin: Equipment like our water jetter can be marked up significantly because customers don’t have a reference point for these costs.

- Market Opportunity: As we found, the market often overcharges for equipment use. By understanding our actual costs, we could offer better prices and attract more customers.

4. Vehicle

- Variable Markup Margin: Costs include fuel, maintenance, and depreciation. Customers are less aware of these costs, giving us flexibility in markups. I often would just combine these costs into the labor costs but understanding these costs is essential.

5. Subcontractor

- Pass-Through Costs: We might add a small markup for coordination, but since subcontractors have their own rates, the margins here are usually modest.

6. Other

- Miscellaneous Costs: Permits, disposal fees, etc. These are often passed through at cost or with a minimal markup.

Understanding Price Elasticity

Price elasticity refers to how sensitive customers are to price changes. Here’s how it played into our strategy:

- Labor: Highly elastic. Customers know the going rates and will push back against high labor costs.

- Materials: Moderately elastic. Customers might recognize material costs but are generally accepting of standard markups.

- Equipment: Inelastic. Customers often don’t know the cost of specialized equipment usage, allowing for higher markups. If they have a reference point, its a rental cost which is usually very high.

By adjusting our markups according to elasticity, we optimized our pricing:

- Competitive Labor Rates: Keeping labor markups low ensured we didn’t lose customers over perceived overcharging.

- Maximized Material Margins: Leveraging supplier discounts while applying standard markups boosted our margins without raising customer eyebrows.

- Strategic Equipment Pricing: Lowering our equipment charges (like with the water jetter) attracted more customers while still providing hefty profits.

The Role of Flat-Rate Pricing

While cost-plus pricing became a cornerstone of our strategy, We realized that there’s still a place for flat-rate pricing, especially for repetitive and straightforward jobs. Services like basic drain cleaning or standard faucet installations are routine and predictable in terms of time and materials. Offering a flat rate for these jobs simplifies the process for both us and the customer.

However, it’s crucial to keep an eye on the costs associated with these flat-rate services. Costs can creep up over time due to supplier price increases, changes in labor rates, or new regulatory fees. If we’re not vigilant, these creeping costs can erode our profit margins.

By regularly reviewing and adjusting our flat-rate prices based on actual costs, we ensured these services remained profitable. This hybrid approach—using cost-plus pricing for complex or variable jobs and flat-rate pricing for routine tasks—provided the best of both worlds. It offered simplicity and transparency for customers while maintaining healthy margins for our business.

Implementing the Strategy

After adjusting our pricing model, we saw immediate results:

- Increased Market Share: Our competitively priced services drew in more customers, especially from property management companies seeking reliable and reasonably priced services.

- Higher Profit Margins: Even with lower prices on equipment usage, our overall margins improved due to smarter markups and leveraging supplier discounts.

- Enhanced Customer Trust: Transparent and fair pricing built stronger relationships with our clients, leading to repeat business and referrals.

A Funny Anecdote

One of our long-time customers, a property manager named Lisa, called me one day.

“Rob,” she said, “I have to ask—how are you offering such low prices for sewer jetting? Everyone else charges a fortune!”

I chuckled and replied, “Well, Lisa, let’s just say we found a way to keep our costs—and your prices—down without cutting corners.”

She laughed and said, “Whatever you’re doing, keep it up! You’ve got all my business from now on.”

Little did she know, our secret weapon was simply understanding our costs better than our competitors.

Key Takeaways

- Different Costs Require Different Markups: Not all costs are created equal. Understanding which categories can bear higher markups without scaring off customers is crucial.

- Leverage Supplier Relationships: Discounts from suppliers can significantly boost your margins when you apply standard markups on retail prices.

- Understand Price Elasticity: Knowing how sensitive customers are to price changes in different categories helps in setting competitive yet profitable prices.

- Monitor Flat-Rate Services: For repetitive jobs, flat-rate pricing offers simplicity, but keep a close eye on costs to prevent margin erosion.

- Transparency Builds Trust: Providing itemized costs (without revealing too much) can reassure customers and reduce price objections.

- Stay Competitive on Labor Rates: Since customers are familiar with labor costs, keeping these rates competitive helps in customer retention.

Why Cost-Plus Pricing Beats Solely Flat-Rate Pricing

- Customization: Each job is priced according to its specific costs, leading to fair pricing for both the business and the customer.

- Profitability: By applying appropriate markups to each cost category, you ensure that every job contributes positively to your bottom line.

- Competitive Edge: Understanding and leveraging the differences in cost categories allows you to offer better prices without sacrificing profits.

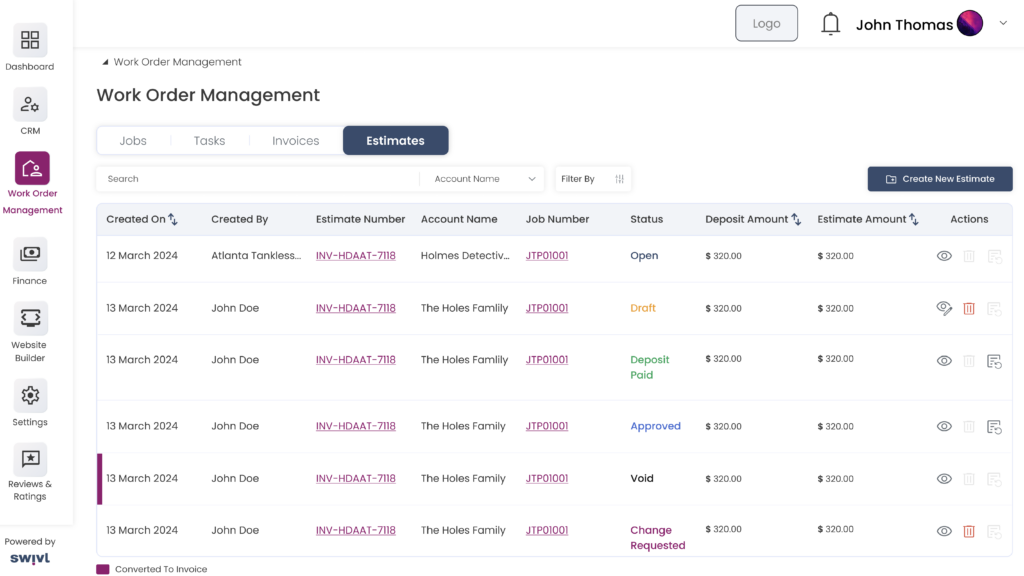

Making It Work with Swivl

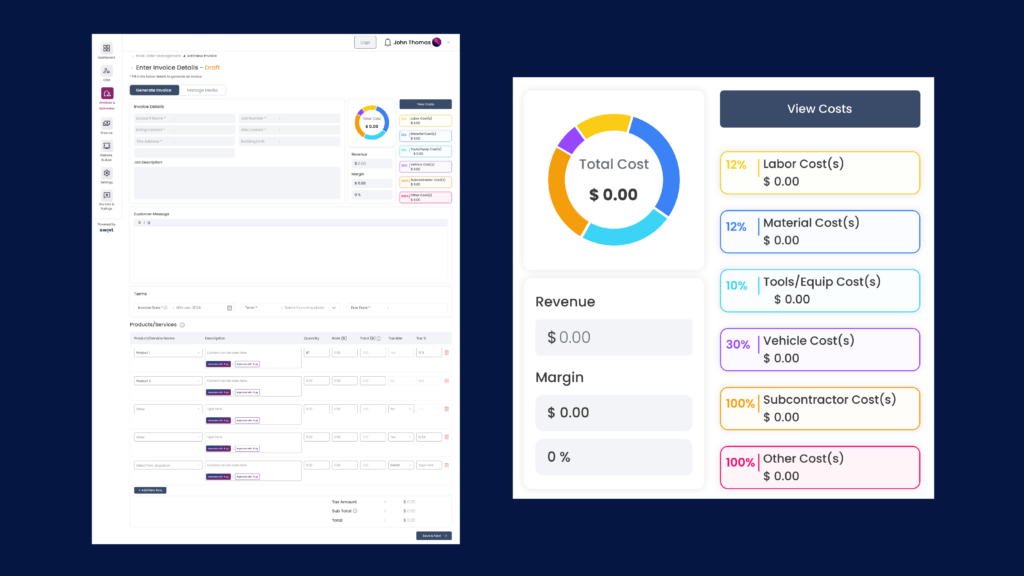

Implementing this pricing strategy might seem complex, but tools like Swivl’s Cost Margin Calculator make it manageable:

- Easy Cost Categorization: Break down costs into the six categories effortlessly.

- Customizable Markups: Assign different markup percentages to each category based on your strategic goals.

- Real-Time Calculations: See your target revenue and margins instantly, helping you make informed pricing decisions.

How It Works So Easily with Swivl

Swivl streamlines cost-plus pricing, making everything from estimating to invoicing easy, accurate, and highly detailed. Here’s how Swivl’s unique tools make cost-plus pricing simple for field service businesses:

1. Effortless and Detailed Estimating

With Swivl’s Cost Margin Calculator, estimating job costs becomes a breeze. For each job, you can:

- Estimate Technician Hours: Quickly estimate hours based on the type of work and skill level required.

- Select Vehicles and Predict Trips: Choose vehicles needed for the job and estimate trips, incorporating vehicle costs directly into your estimate.

- Multiple Subcontractor Bids: Swivl allows you to create multiple bids for subcontractors, so you can compare costs, ensure you’re getting the best price, and keep subcontractors honest.

- Automatic Material Extraction: Upload a supplier quote, and Swivl extracts each item, automatically applying your chosen markup. This lets you show customers a fully itemized materials list with just a few clicks, boosting transparency and reinforcing trust.

With Swivl’s itemized, detailed estimates, you’ll set yourself apart from the competition, appealing to customers’ elasticity bias and showing them real value.

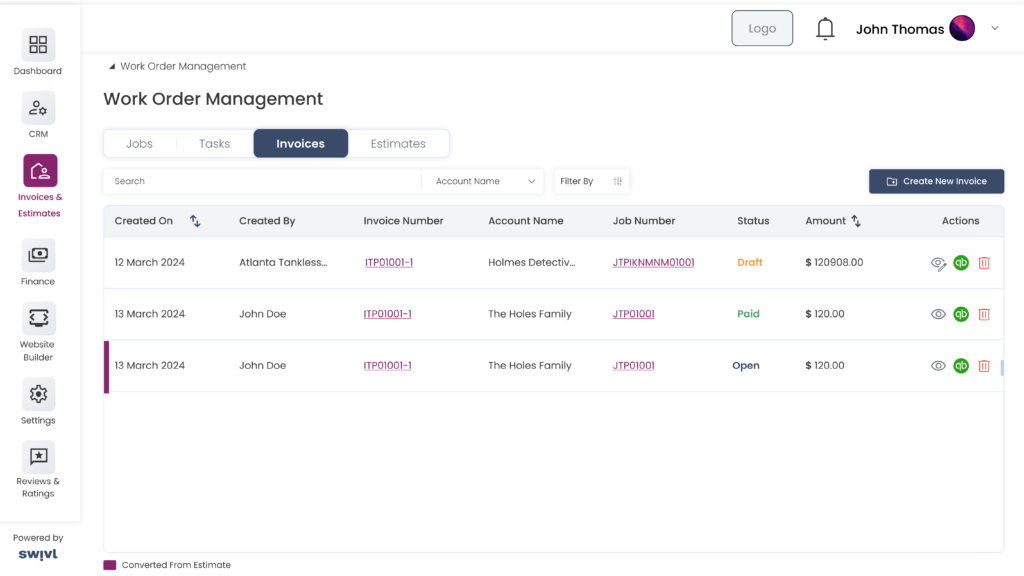

2. Automated, Accurate Invoicing

Swivl’s invoicing tools automate job costs, saving time and improving accuracy:

- Labor Costs: Calculated from technicians’ clock-in and clock-out times.

- Vehicle Costs: Based on actual mileage tracked during each job.

- Materials: Easily carried over from the estimate, with the flexibility to adjust quantities or add/remove items as needed.

- Equipment Costs: Calculated based on actual hours used, so you only charge for what’s needed.

- Subcontractor and Other Costs: Can be added as they come in, keeping invoices updated.

With these tools, every invoice is accurate and comprehensive, providing customers with clear insights into each cost.

3. Real-Time Job Cost Insights

Swivl’s automation doesn’t just simplify pricing—it also provides real-time insights into job costs. Once a job is complete, Swivl lets you compare estimated and actual costs, helping you understand how accurate your initial estimates were and pinpoint areas for improvement. This feedback loop helps you fine-tune your pricing strategies, making your estimates more reliable and your margins more sustainable over time.

With Swivl, cost-plus pricing becomes intuitive, efficient, and easy to manage, helping you set profitable prices, keep subs competitive, and deliver the transparent, detailed pricing your customers appreciate.

Final Thoughts

Switching to cost-plus pricing transformed my business. It wasn’t just about making more money—it was about making smarter money. By understanding the nuances of each cost category and how customers perceive them, we optimized our pricing strategy to be both competitive and highly profitable.

But remember, flat-rate pricing still has its place. For repetitive, straightforward jobs, it offers simplicity and ease of understanding for customers. Just be sure to regularly review these flat rates to ensure that creeping costs don’t eat into your margins.

So, if you’re still relying solely on flat-rate pricing, consider adopting a hybrid approach. Dive into cost-plus pricing for complex jobs and keep flat rates for the routine ones. You might discover hidden opportunities—like we did with our water jetter—that can propel your business forward.

Remember, good pricing strategy starts with good costing knowledge. Don’t leave money on the table because of outdated pricing models. With tools like Swivl, you can take control of your pricing and, ultimately, your business success.

Ready to revolutionize your pricing strategy? Swivl makes it easy!